Major Industries That Use litho printing Today

Wiki Article

A Comprehensive Guide to Comprehending Litho Printing Strategies

The world of litho printing, a strategy stemming from the late 18th century, is an interesting mix of history, art, science and innovation. This comprehensive guide will certainly decipher the complexities of this printing method, from the structure of litho inks to the challenges dealt with in modern applications. As we venture into the intricacies of lithography, the significance of automation and sustainability in guaranteeing its future relevance ends up being increasingly clear. Stay with us as we journey into the fascinating world of litho printing.The Historical Evolution of Litho Printing

The historical trajectory of litho printing, a pivotal innovation in the world of interaction, is a captivating story of human ingenuity. The procedure progressed with the advent of the rotating press, which greatly enhanced efficiency. Each phase of litho printing's development showcases humankind's unrelenting search of efficiency and high quality in visual interaction.Translating the Scientific Research Behind Litho Printing Inks

Moving on in the exploration of litho printing methods, the emphasis now moves to the scientific research behind litho printing inks. The make-up of these inks, their drying process, and shade mixing methods create the backbone of this complicated art kind. Comprehending these elements is essential to understanding the craft and achieving the preferred print outcomes.Make-up of Litho Inks

In lithographic printing, the fundamental duty of litho inks can not be overemphasized. Pigments, the color-providing elements, are finely ground particles suspended in the car, a liquid that carries the pigment onto the printing surface. Each element plays an important part in the final print's quality, making the exact formulation of litho inks an elaborate science.Ink Drying Refine

From the make-up of litho inks, interest transforms to the interesting procedure of ink drying. The drying out process is critical, as it impacts the final print's quality and longevity. Two main approaches are made use of in litho printing: oxidative drying out and absorption. Oxidative drying out entails the ink responding with oxygen in the air to create a difficult, dry film. This approach offers a durable finish, yet can be slower contrasted to absorption. Absorption, on the other hand, involves the ink seeping into the paper fibers, which is a quicker procedure but can lead to much less lively colors. The option between these approaches depends on variables such as print speed requirements, the paper kind made use of, and the wanted coating.Shade Mixing Techniques

While the drying out process plays a key duty in litho printing, the scientific research of shade mixing strategies holds equivalent relevance. This is an intricate procedure that entails the mindful blending of primaries: cyan, magenta, and yellow, in differing percentages to accomplish a large variety of shades. The addition of black ink, called 'crucial', assists in controling the strength and depth of the shades. The scientific research behind litho printing inks additionally thinks about the openness of the ink, which affects exactly how shades overlay and mix. To accomplish an effective shade mix, print professionals have to likewise understand the ins and outs of ink behavior, color concept, and the physical residential properties of the substratum on which the ink is applied.The Art and Style Aspects in Litho Printing

Litho printing breathes life into art and design with its distinct components. Litho printing fits a range of colors, making it possible for artists to produce lively and vibrant prints. This combination of precision and flexibility makes litho printing a favored option for lots of musicians and developers.Modern Applications of Litho Printing Techniques

Litho printing methods have located extensive use in the contemporary commercial market. Its influence and value remain to expand with the introduction of brand-new advancements and technologies in the field. This area will certainly discover these modern applications and the transformative duty they play in the printing market.

Industrial Litho Printing Uses

Litho printing stays a critical part of the business industry. High-volume printing tasks, such as the production of publications, newspapers, and product packaging, depend on litho printing for its capacity to provide premium photo top quality and price performance. Litho printing additionally check out this site provides a wide shade spectrum, exceptional to that of electronic printing.Advancements in Litho Printing

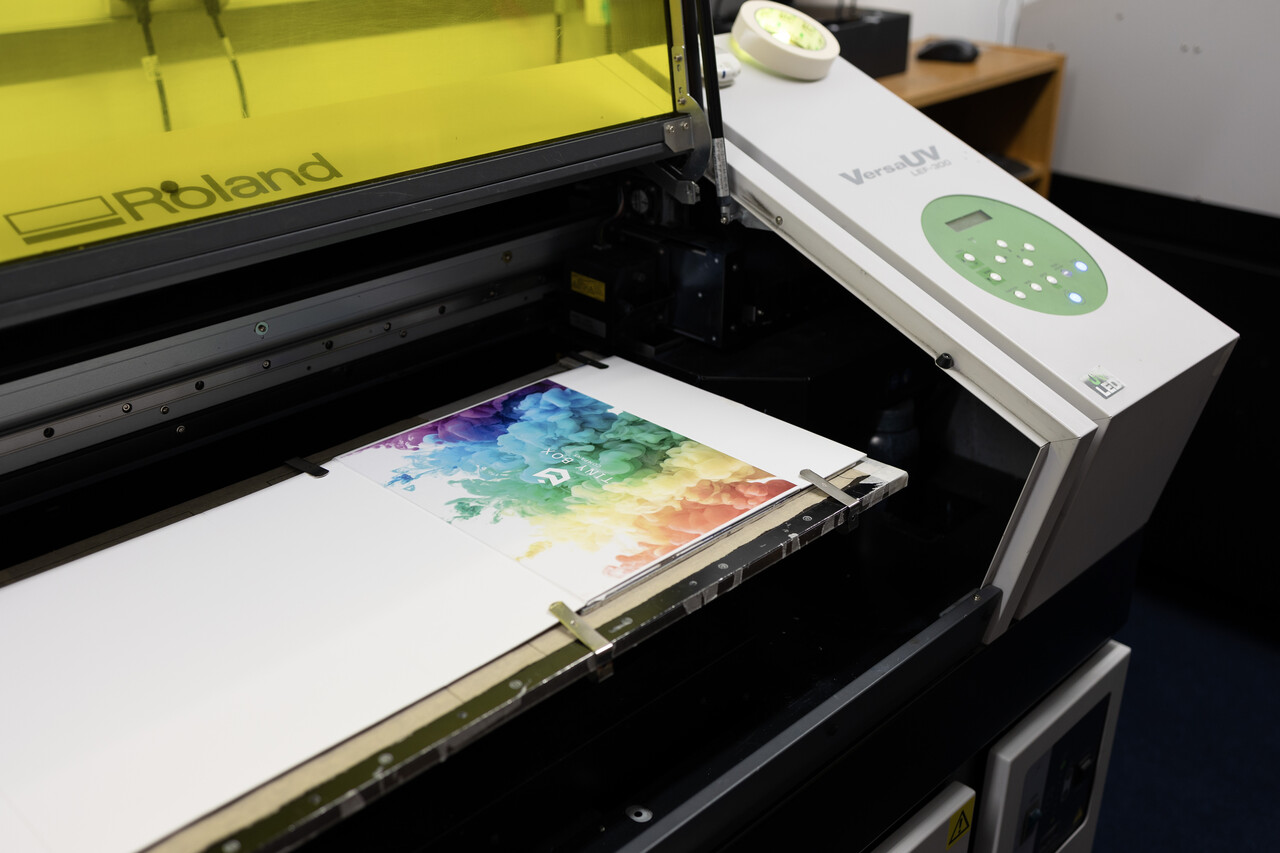

Pushing the borders of typical methods, modern innovations have sustained a host of technologies in litho printing. One popular advancement is electronic litho printing, which incorporates the merits of digital technology with litho's high-quality outcome. These technologies underscore the long-lasting relevance of litho printing in the contemporary world.Checking out the Process of Litho Printing: Action by Step

Difficulties and Solutions in Contemporary Litho Printing

Despite the precision and practice that litho printing proudly upholds, it is not without its set of modern difficulties. Digital litho printing enables for affordable short runs and simple customization, resolving the problem of variable information. Home Page Therefore, while there are obstacles, the litho printing market is proactively adapting to satisfy them head-on, ensuring its importance in the future.

Conclusion

To conclude, litho printing, with its rich history and clinical details, holds a substantial place in the print sector. As the overview reveals, it's a synthesis of art and technology, with contemporary improvements guaranteeing its relevance. The industry deals with difficulties that need ingenious options, with an emphasis on automation and sustainability. The future of litho printing rests on its ability to adapt to these changing needs, attesting its enduring worth in an advancing market.

Report this wiki page